Manufacturing technology

Scroll

Manufacturing Technology

Cold forging,Precision cold forging

A precision micron unit forging technology performed under normal temperature. ISSI corporation realizes high accuracy, meeting the lowest fluctuation conditions (fluctuation min) by employing precise die design and process control technology that makes full use of digital technology (CAE analysis).

Cold forging, Thin Molding

Thin molding through the combination of frictional resistance controlling tribology technology, die technology, and forging technology. Thin molding is a technology that omits the costly, time consuming cutting process by finishing products with a high-precision, perfectly circular thin wall.

Heteromorphic Cold Forging

We achieve approximately 2 times the productivity of conventional forging presses by molding asymmetrical shafts and eccentric weld bolts with a forging former.

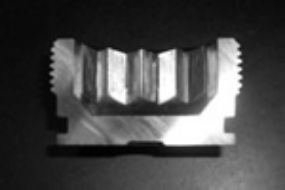

Composite Technology (Forging + Rolling)

We realize strength and high-level precision by combining a forging technology and rolling technology.

Hot Forging

Hot forging is a technology that keeps forging materials in a heated state of 1100–1250 degrees Celsius. Hot forging can be used for the production of relatively big products without losing malleability.

Warm forging

Warm forging is a technology used to forge materials in a heated state of 200–850 degrees Celsius, which is lower than hot forging. Warm forging is used to forge materials that are difficult to mold like high-carbon steel, which maintains the material’s strength.

Hydro Tube Forming

A processing technique that blows up a metal pipe by fluid pressure and rubber pressure to make shapes freely along a die. Hydro tube forming products are used for automobiles, transportation equipment, agricultural machinery, construction machinery, construction hardware components, and so on.